Laser Cutter Rotary Tool

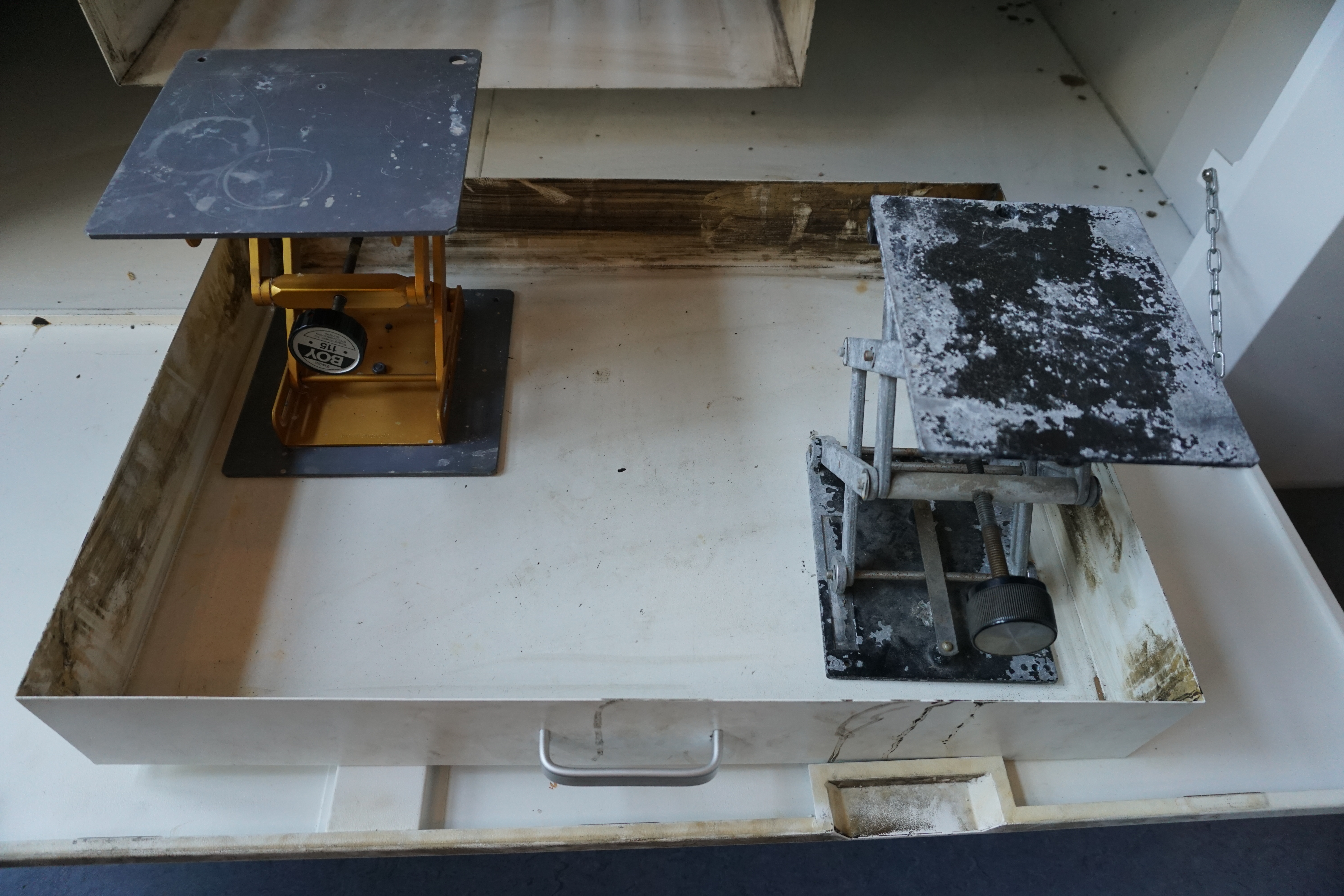

The rotary tool can be used in conjunction with any of the CO2 lasers to engrave glass bottles, vases, or anything cylindrical. Essentially, it works by converting movement in the laser cutter's y-axis from translational to rotational motion, without the need to change the machine at all! The only limitation is that it can only be used in scan mode.

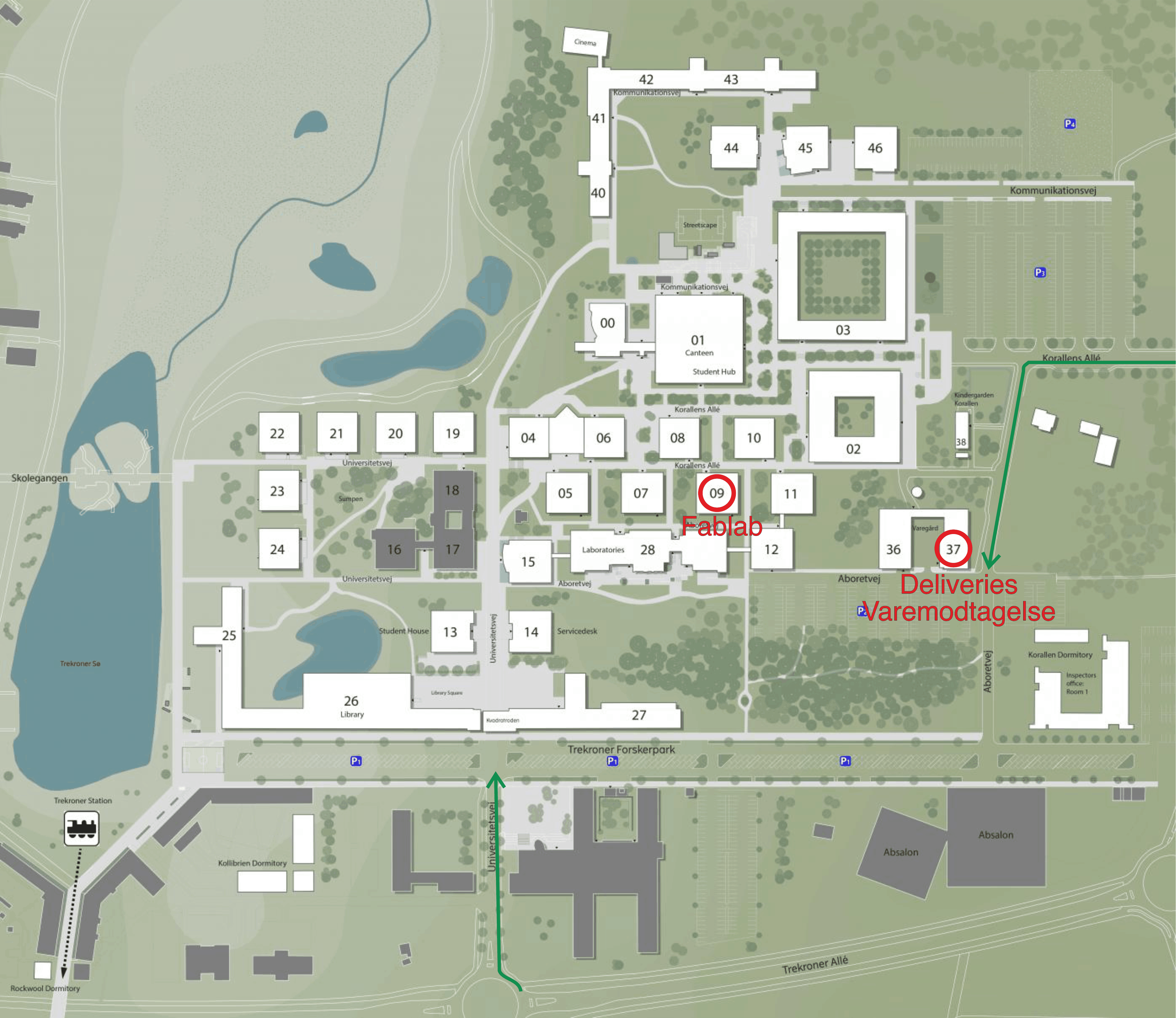

Unfortunately the laser beds need some adjustment before the tool can be used. Start by removing most of the bars from the laser cutter base as seen below.

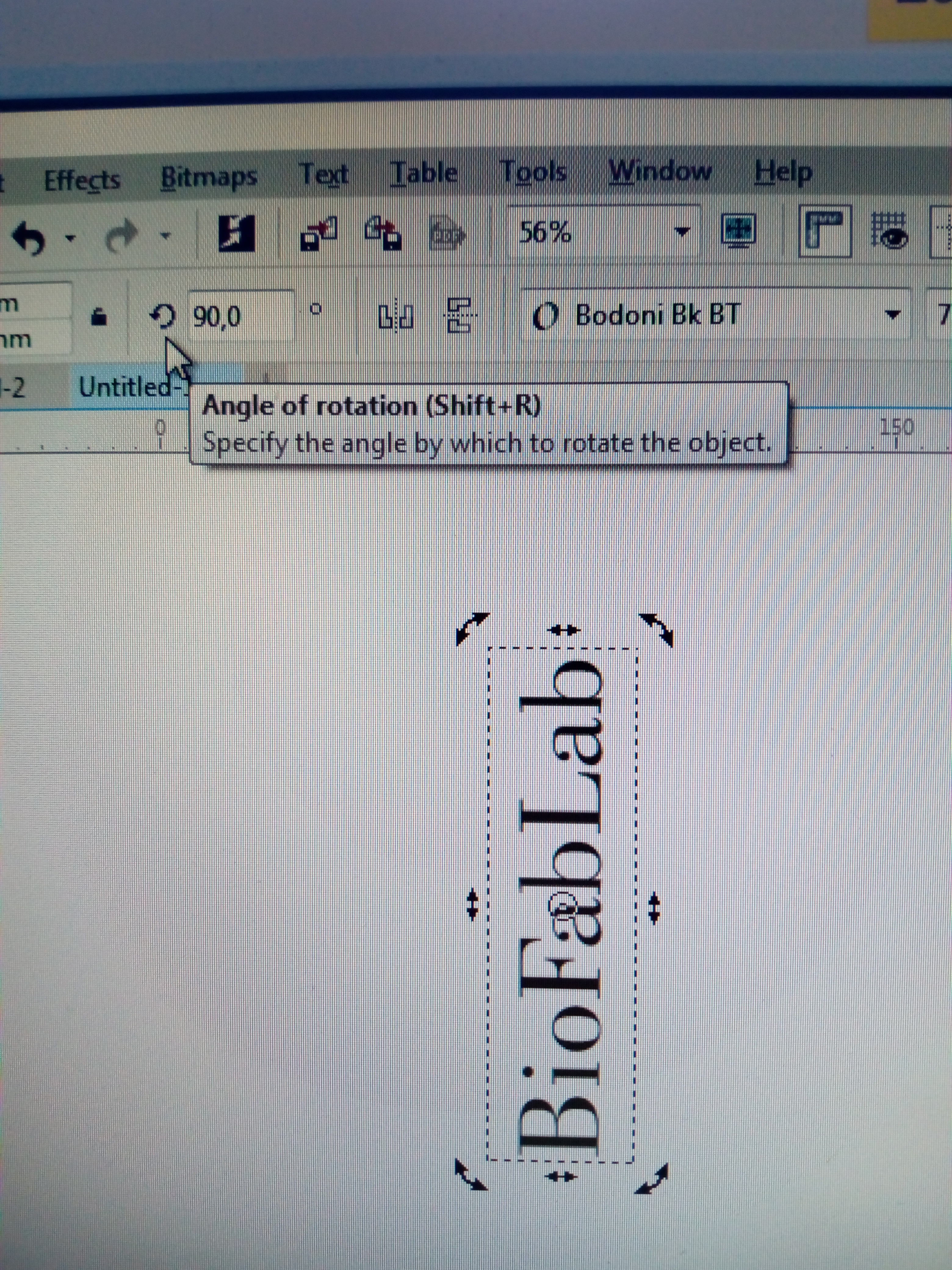

Remember to use only the scan setting, as none of the other modes will work with this tool yet. The scan parameters for glass can be found attached to one of the computers in the laser cutter room.

Remember to use only the scan setting, as none of the other modes will work with this tool yet. The scan parameters for glass can be found attached to one of the computers in the laser cutter room.

Everything should now be ready. Happy engraving!