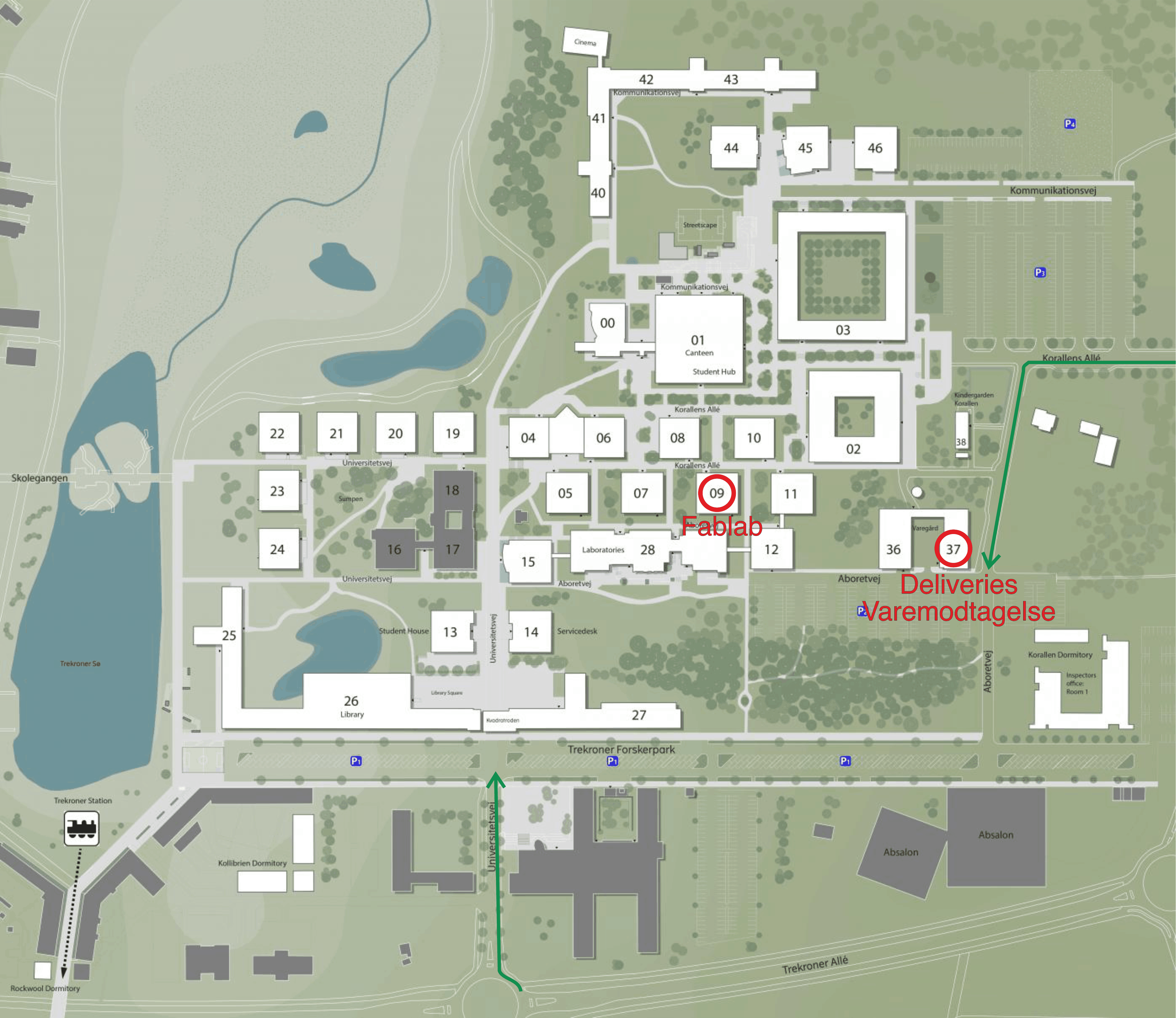

CNC milling [small]

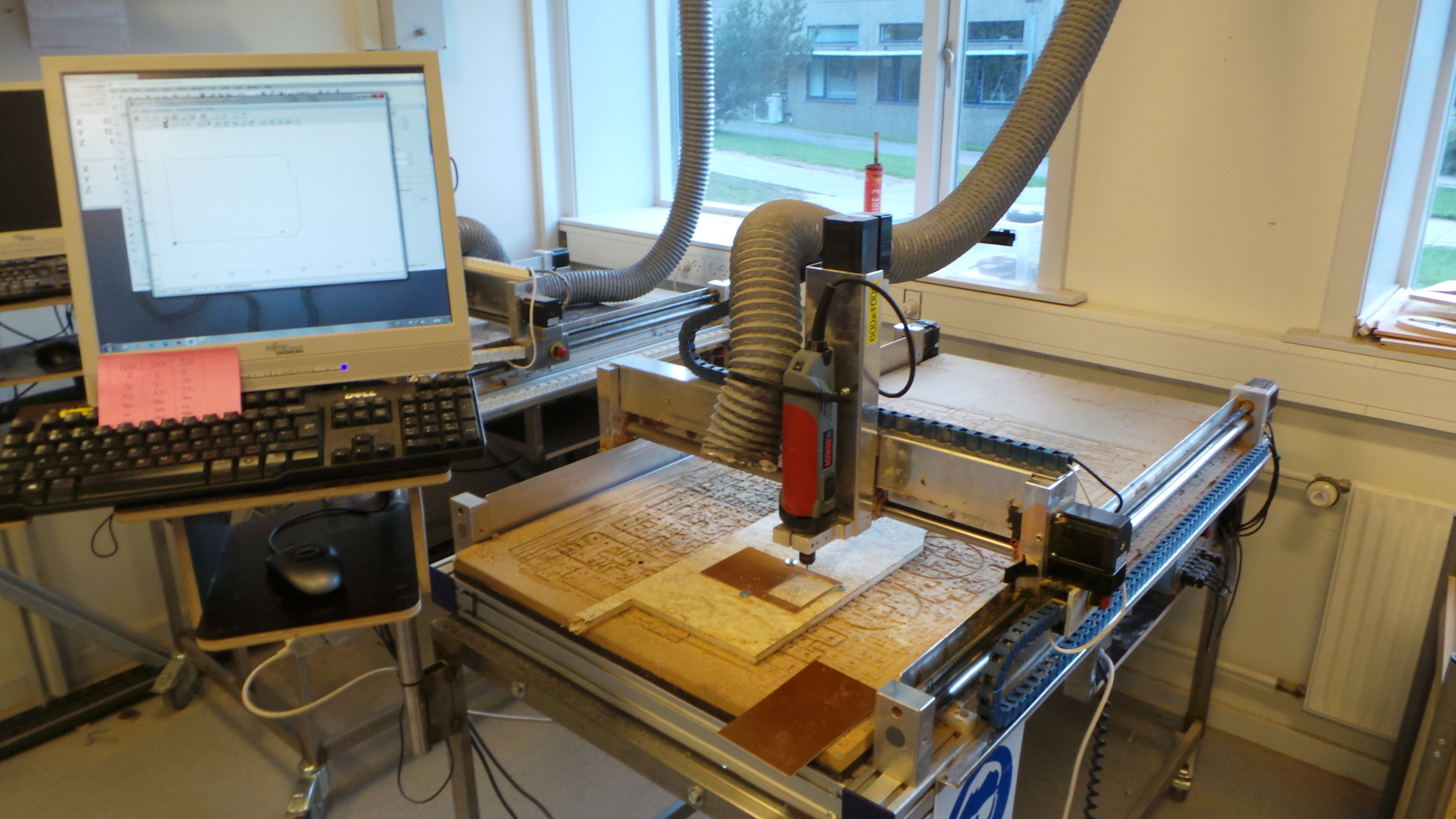

CNC machine with 1000 x 600 x 100 mm working area for lightweight materials such as plywood, wood, MDF, foam, plastics, nylon, printed circuit boards, aluminium.

2 High-Z S-1000 CNC Routers with Normally equipped with a Kress 20.000 RPM spindle carrying a 3mm mill, can be equipped with 1-5 mm mills. Precision under 0.1 mm. The Z axis travel is 120mm, but some of that will usually be used up by the mill - depending on the length of the cutting tool you want to use.

Guide

This Guide takes you through the basic steps of using the small cnc in the lab.

Startup:

(1) Turn on computer and boot Windows (DO NOT TURN ON MOTOR CONTROLLER).

(2) After windows boots turn on motor controller (under the table).

(3) Run WinPC-NCEconomy:

(4) Perform reference move (move machine to upper left corner)

(4) Perform reference move (move machine to upper left corner)

Checklist:

(1) Does workpiece fit in machine without hitting edges or fastening? (2) Is zero point x,y,z, set to lower, left, top corner of material? (3) Is tool speed and measurement set up (4) Is ventilation turned on.

Routing

(1) Load a .plt (from COrelDraw) file into WinPC_NCEconomy.

(2) Note which layers are used (upper left corner).

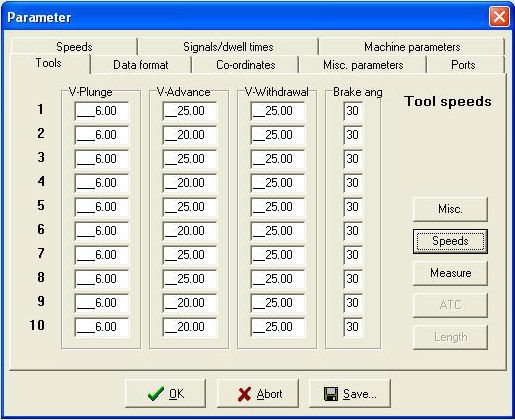

(3) In tools menu set measurements for each layer. If more cuts are required for desired depth set layers to max for given material.

(3) In tools menu set measurements for each layer. If more cuts are required for desired depth set layers to max for given material.

MAKE SURE TO SELECT THE “Measure” BUTTON ON THE RIGHT

MAKE SURE TO SELECT THE “Measure” BUTTON ON THE RIGHT

(4) Select speed for each layer in tools menu. Typically same speed for all used layers. MAKE SURE TO SELECT THE “Speeds” BUTTON ON THE RIGHT

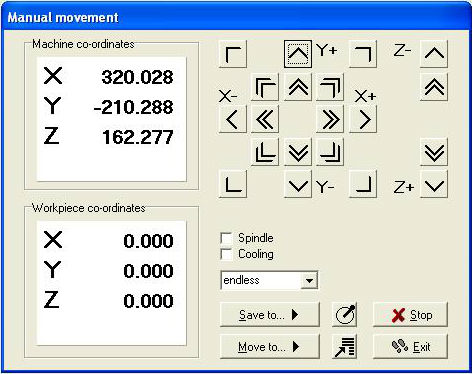

(5) In move menu use arrows to move tool to lower left corner of the material. Position the tool so that it just touches the material. Use the slow arrows for the final approach and be careful not to press the tool into the material.

(6) When the tool is touching the lower left corner select: ‘save as xyz zero point’ from the ‘Save to’ drop down menu.

(6) When the tool is touching the lower left corner select: ‘save as xyz zero point’ from the ‘Save to’ drop down menu.

(7) Select first layer to route. Typically holes in the workpiece. (allways do outmost cut last).

(8) Press start (graph button upper left corner).

(7) Select first layer to route. Typically holes in the workpiece. (allways do outmost cut last).

(8) Press start (graph button upper left corner).

Settings for various materials

Plywood 15 mm:

Tool: 5mm Cylindrical router.

Feed: 15 mm/s.

Plunge: 6 mm/s.

Max depth per cut: 16 mm.

Plywood 12 mm:

Tool: 3 mm. fishtail or 5mm cylindrical router.

Feed: 25 mm/s.

Plunge: 6 mm/s

Max depth per cut: 6 mm.

Plywood 4mm:

Tool: 1-3 mm. fishtail router.

Feed: 20 mm/s.

Plunge: 6 mm/s.

Max depth per cut 5 mm.

Circuit board:

Tool: 1-2 mm. fishtail.

Feed: 15 mm/s.

Plunge: 6 mm/s.

Max depth per cut 4 mm.