Using CNC machines in ceramic design

By: Jonas Wilson Schnack

Having been in a relationship with a classical educated potter and ceramicist for quite a few years, I have naturally been fascinated with the craft. I am myself a self-taught designer and programmer, but creation is creation, and I have wanted to be able to work with materials like clay and stoneware for quite some time now.

My adventures into the area began a few months back when my partner and I decided to open a ceramic workshop and store in Gentofte (www.vondererde.dk or facebook.com/dererde ). I started building an UltiMaker 3D printer with the purpose of printing my designs, which would then be made into plaster molds, for casting liquid porcelain in.

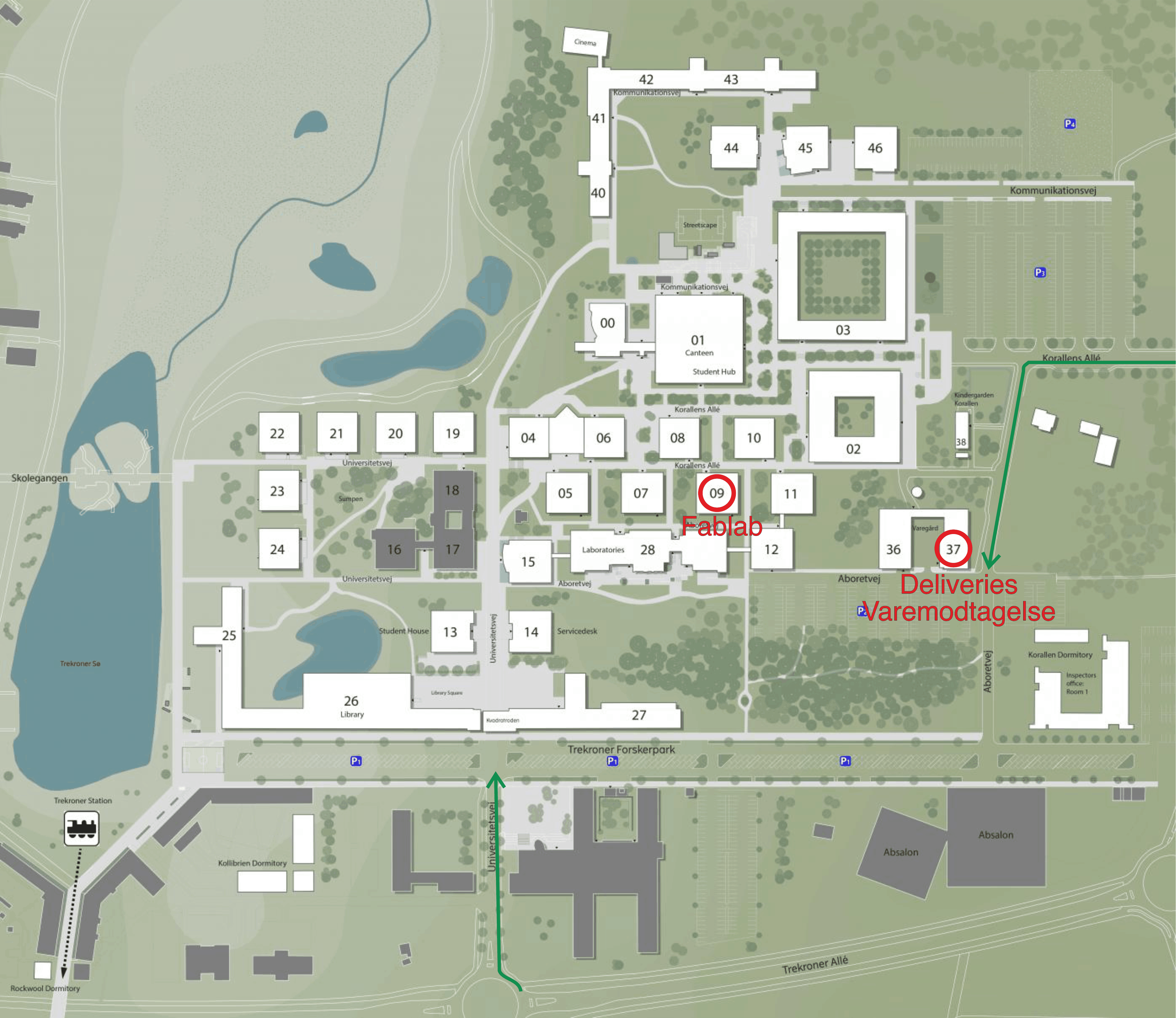

During the building of the UltiMaker, I became aware of FabLab at RUC. I came there to have the wooden parts of the printer lasercut, but seeing the facilities, my mind started to wonder whether 3D printing was the only way to produce my shapes.

I have had plenty of problems with the inevitable layering produced by the 3D printer, but I am slowly learning what works and what doesn't.

Not so long ago I got the idea of using the layering as part of the design, and decided to upscale the layer heights to extremes, so that I could manually slice the 3D shape, and lasercut the slices one by one. I have decided to use 6mm and 4mm layer heights as these thicknesses are readily available in HDF and MDF boards.

After cutting the layers I glue them together, and lacker them, hoping that the plaster will not stick too much to the wood. My first attempts at making molds from these shapes have not been successful, but I am still learning to mix the plaster right, and experimenting with different slip agents, so the adventures will continue.

If anyone has experience with the techniques I am trying out, or are just interested in joining my adventures, I would be pleased to share the little knowledge I have gathered so far.

I am very happy to have found FabLab at RUC, and look forward to finding new ways to manifest my designs.