Project mimir: 3D printing houses

What if one could 3D print a whole house?

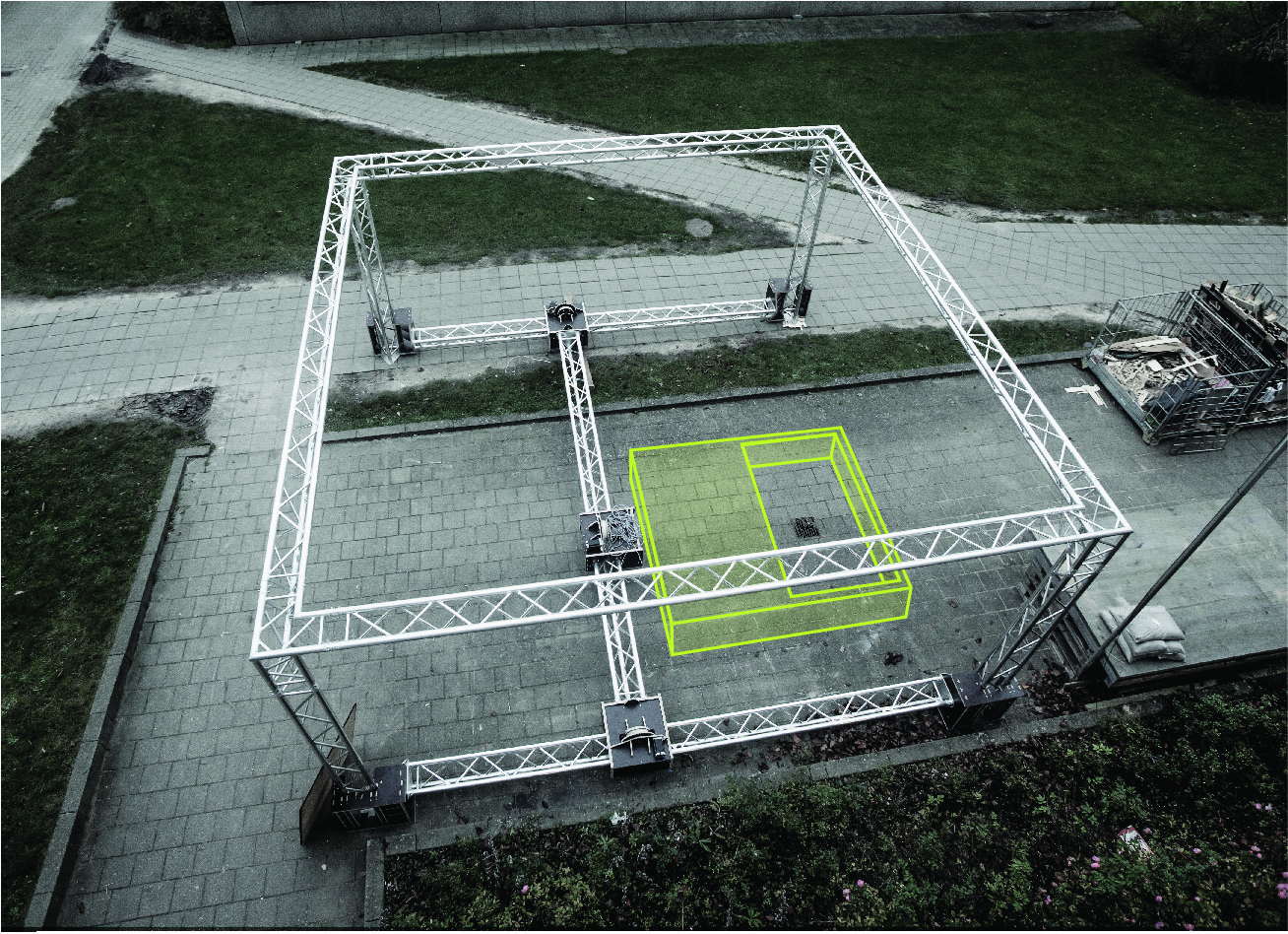

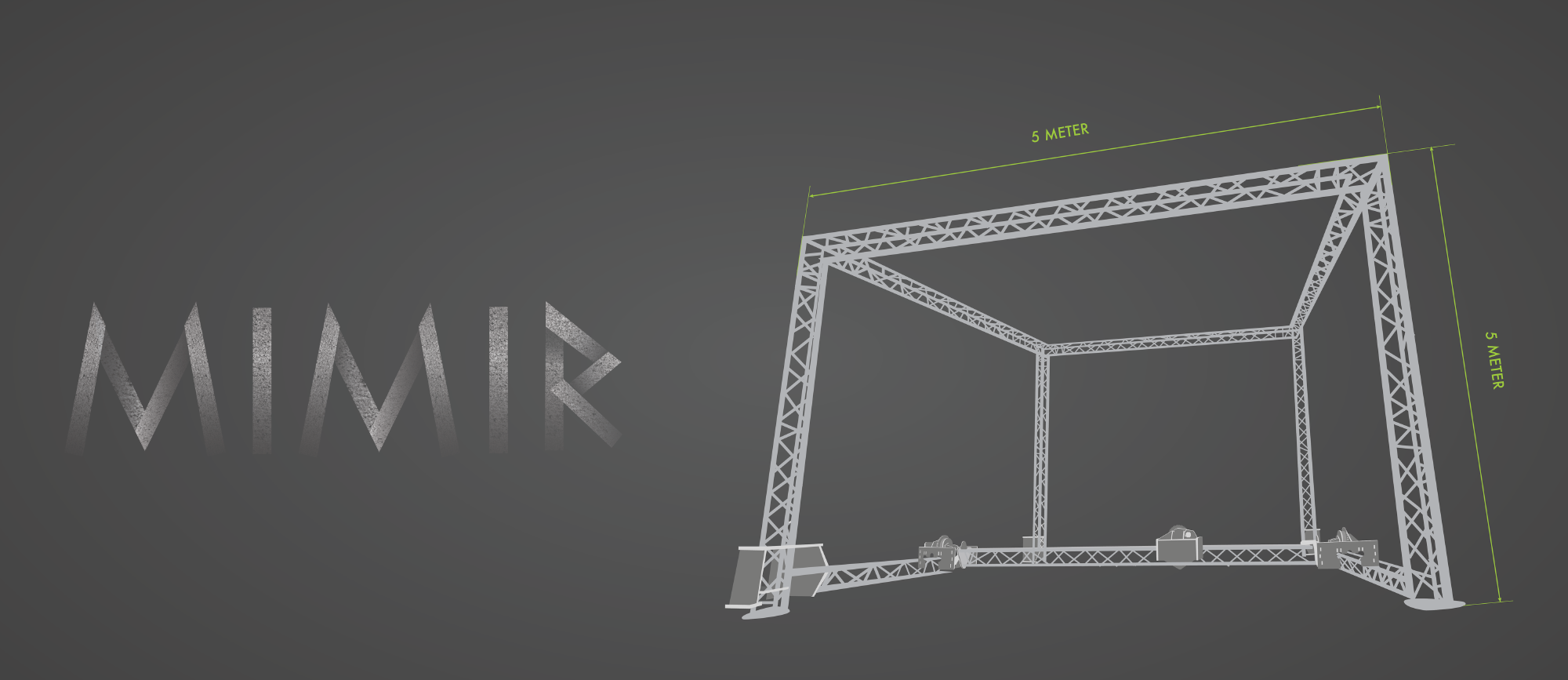

We explore future potentials of 3D printing houses. This is done by building a 5x5x5 meter 3D printer which uses concrete as its construction material. By actually building a 3D printer this size it is possible to try out the potential of the technology and start to a create discourse about future living conditions based on this manufacturing method. What are the aesthetic possibilities of this construction process, how does it relate to us a humans and what alternative structures can be produce?

House construction today is mostly based on prefabricated concrete parts which are combined into house constructions. Largescale 3D printing strategies may enable us to move beyond this paradigm and start construction one of a kind constructions. The last two decades 3D printing has been used to romanticize the ideals of fast, eco-friendly and custom manufacturing houses. With project Mimir we explore the feasibility of this potential. Is it a romantic dream of the future or is it actually feassible to 3D print constructions this size?

The vision of large scale 3D printing

We are now at a crossroad wherein large scale 3D printing has to prove itself as a construction technique with new potentials. Many people have contemplated on its potential. Among many things the following are the ideas that one hope to unleash:

- On location production: The ability to 3D print large concrete parts on site. Instead of predesigning and transporting to the build site the 3D printer will enable constructers to make components right at the build site. This way only the concrete in powder form has to be transported.

- Unique custom designs: With massive house constructions appearing within cities the visual aesthetics can become repetetive. Through the 3D printing technique it may be possible to construct individual appearences for parts of a house or between house with the same base structure. This would normally require the production of concrete molds.

- Extreme scenarios: Using at 3D printer can become a way to build in extreme situations. One such thing could be on the Moon another could in the desert.

- Complex forms and aesthetics: The computer controlled build process enables for much more experimentation of complex forms e.g. double convex and convave. The enables for more interesting easthetics than the squary structures that tends to dominate concrete construction today.

- Less waste: A common notion is that 20 percent of all build materials are wasted at construction sites. The short process between base materials (concrete powder + water etc.) to constructions leaves less cut-a-away waste.

- New properties: With 3D printing it may be possibel to design now proporties within the material. This could be composite constructions consisting of multiple types of material. E.g. experiments has been done with bare fiber optics to provide ligth between spaces. It could also be possible to have a tigther integration to the insulation process, by embedding it into the concrete itself.

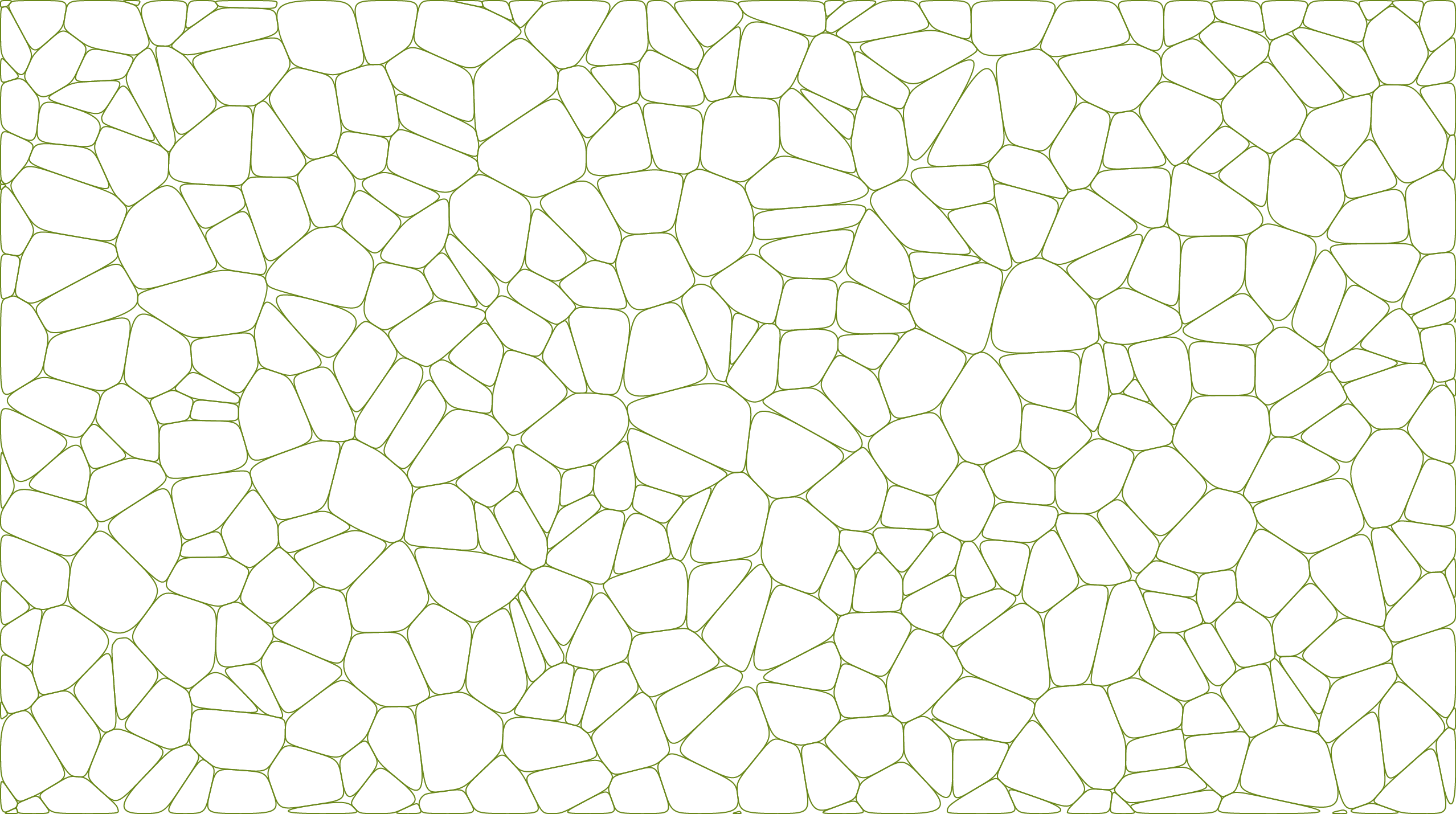

From computer generated design to a physical form

Computer(ized) Numerical(ly) Control(led) systems like a 3D printer enables us to computationally generate rather intricate constructions and convert them into physical form. E.g. the rather complex beehive pattern below does not have a repeatable pattern, but can be a combination of unique shapes which results i a square. When 3D printed this could be turned into a lightweight custom structure like a wall element:

The above beehive like structure has been 3D printed on a small 3D printer in PLA material and will be printed in concrete over the next months.

When printed in concrete it can become elements of a larger house:

First Nordic large scale 3D printer

Few experiments with this type of 3D printing har already been conducted for various construction porpuses around the world. None of the projects have yet to produce feasible outside-the-lab results. By building our own 3D printer we seek to contribute to this design experimentation.

First and foremost we believe that it is neccessary to have our own working 3D printer to be able to explore the potential of them. Further we believe that it is outmust important to put the Nordic reqion with it long line af architectural work in front of this new wave of construction technology.

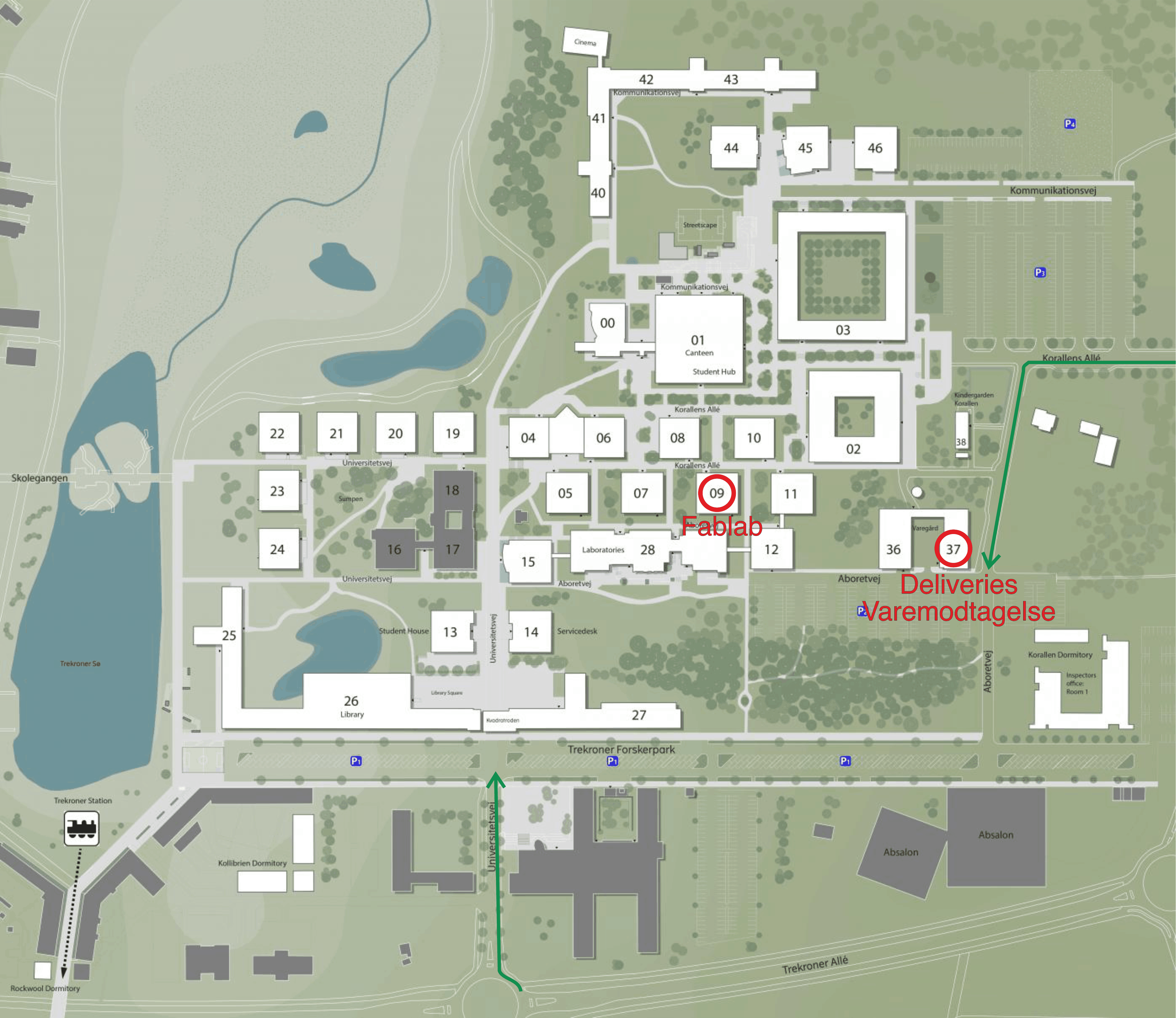

Fablab as an unique environment for large scale 3D print development

The idea of creating the first nordic large-scale 3D printer came to be in October. Within 3 months a budget of merely 75.000 Dkk the first prototype was made. As Nicolas Padfield (leader of Fablab Ruc) points out:

"Without the rapid prototyping machinery within Fablab RUC and the skilled competences within the environment it would not have beeen possible to design and build the printer within 3 months"

This rapid and cheap manufacturing enables Roskilde University and Fablab RUC to try out and experiment with large concrete construction experiments and gives us the ability to iterate with multiple solutions to the problems.

Everything will be open-source

In the spirit of the maker movement and the fablab charter all the diagrams and the material list will be open sourced for other Fablabs to reproduce it. The printer itself is build with readily available fablab tools like (cnc milling) and easily available parts like stepper motors and truss used for stage lighting. This enables other fablabs and designers to build upon the work of the design.

The project extends the CNC house experiment from 2014. This project used a large scale CNC mill to mill plywood into assemble shapes for house construction.

First prototype

The first concrete element has been produced from the machinery: