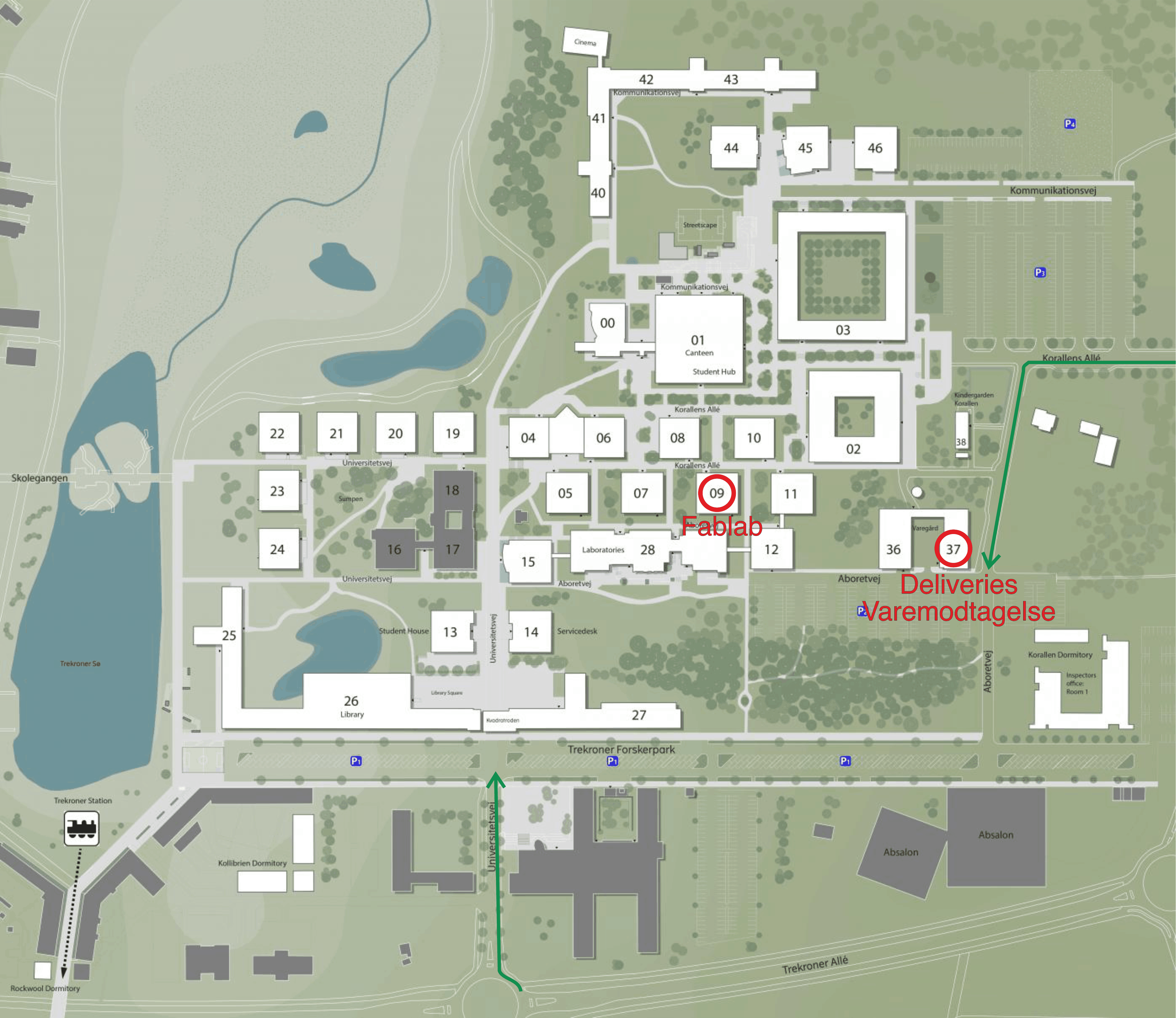

Metal laser cutting

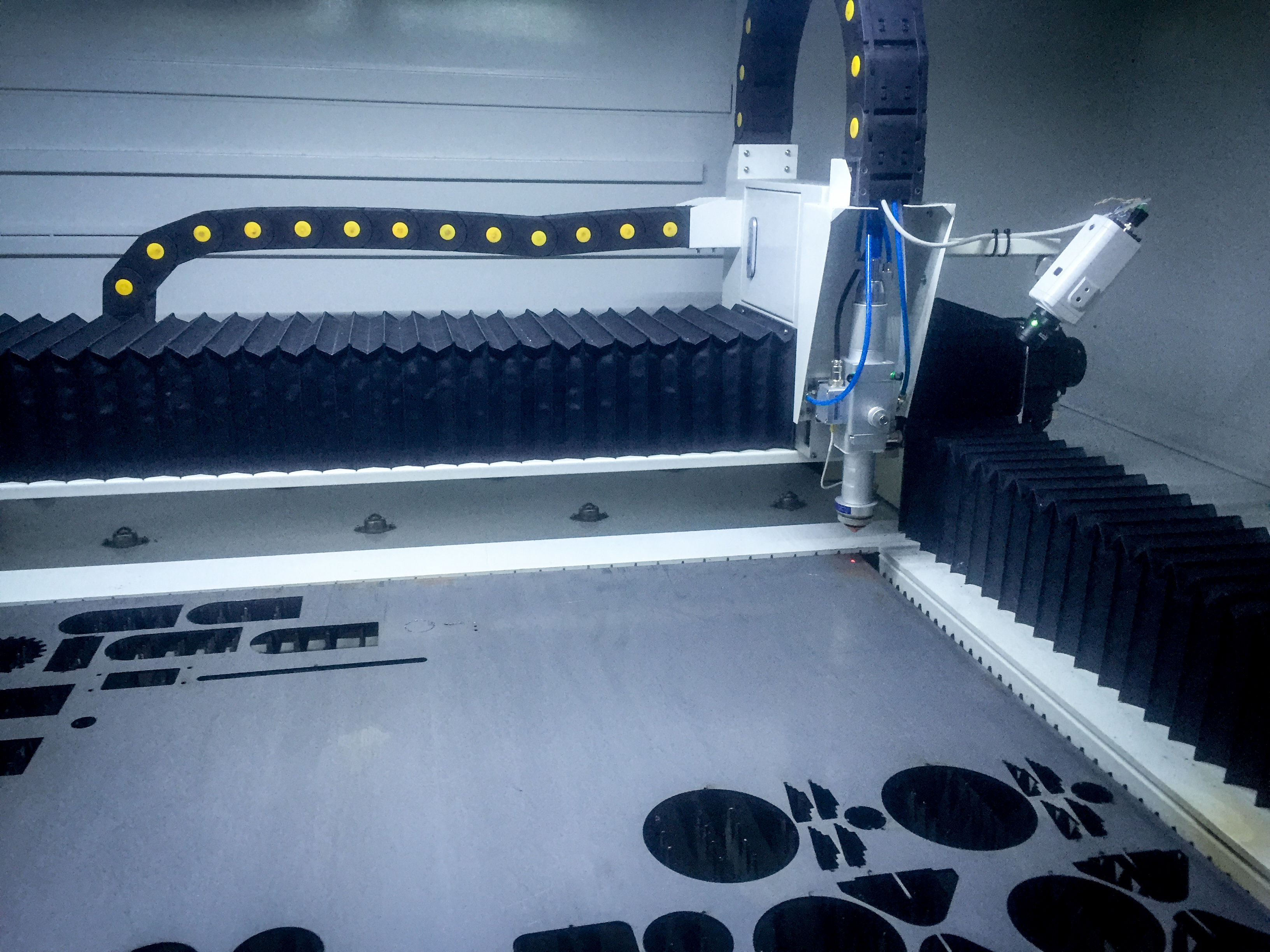

1500W metal laser cutter Use by prior agreement only. It can cut up to (about) 20mm steel, 5mm aluminium, 5mm brass, 5mm stainless. The working area is 1300x900mm.

Confirmed materials there can be cut:

8 mm normal steel

6 mm stainless steel

4 mm aluminum

1 mm copper

We have recently aquired a semiconductor pump ytterbium-doped fiber laser (single-mode continuous) from IPT.

This laser can only be used with a Technology Guru. We have limited time. We are still learning to use it effectively. If you wish to use this machine, you must email a short motivated application explaining

- Who you are

- What your project is

- Size

- How much cutting (approx, in distance travelled. There is a big difference between cutting a 1000x500m sheet with four holes in and a 1000x500mm sheet with 900 intricate details. The laser can usually cut about 80mm per second.

- What materials you will be bringing / that you will be bringing your own materials (Sanistål and Lemvigh Müller are possibilities.)

- A drawing or sketch so we can understand what you are trying to do.

- A couple of suggestions for times, within our opening hours.

to fablab@ruc.dk

- Please consider weight. Steel weighs about 7800 kg per cubic meter. So for example, something 1000x600x4mm weighs 1x0.6x0.004x7800=19 kg.

- Steel sheets are often sold in 1x2m size. These are heavy! And need cutting in half before they can fit in the laser cutter.

- "Metal" is not specific enough. There is a big difference between steel, stainless steel, aluminium, brass etc. Be specific :)

- We do not sell materials.

- If what you are doing is smaller than an A4 sheet, we may have leftovers you can have for free - ask ahead of time.

- Please bring a .dxf file on a USB stick. Not .ai or .svg. Most programs can export .dxf , or you can install an export filter to add this functionality. Otherwise, Inkscape is free, open source and can usually convert.

- All dxfs to be cut from the same material should be combined in one file, as close together as possble (a 2mm gap is suitable) so as to not waste material.

- Curves should be closed - otherwise we can cut it, but not make lead ins so the start of the cut is pretty.

- Bring your computer so you can correct any issues.

- Steel up to about 5mm (3mm for stainless) cuts nicely. Over that there may be dross on the underside of the cuts, which will need removing with a belt sander or similar. Aluminum is challenging for the laser to cut and we only promise to be able to cut 3mm - anything thicker will require testing and special guidance.

- You need about 10mm extra around the edges.

- This laser can not engrave, only cut. We have this laser: https://fablab.ruc.dk/fiber-marking-laser/ for marking metals (and plastics).

- Details: the rule of thumb is that you can cut details as small as the material is thick. So e.g. a 1mm detail in 1mm thick steel is fine. You can also make smaller details, e.g. holes or something that goes to a point. However, if there are long (the metal will have time to heat up a lot more than with "shorter" details) thin (thinner than the material is thick) things you may run into problems. But that doesn't mean it is impossible, it means you need to run some tests first and see if it is possible.

- Please read how do I get started and understand the ethos of this space. We are not your free cutting service and we won't stress over your deadline if you are last minute. You are doing the work, and the purpose is an interesting collaborative creative space. It is a free service, we don't promise anything in the way of outcome, whether we have time etc. If you have deadlines and demands, it is better to pay for commercial service elsewhere.

- The person doing the project and who can do alterations to the drawings has to come. You can't send someone who doesn't really understand what is going on with just a USB stick.

- Occasionally we run out of gas. New gas is delivered once a week, on Tuesdays.